Tissue Bio-Adhesive (Amcrylate – A BIO ADHESIVE)

Concord Drugs has registered its presence in the last one decade in Tissue Bio-Adhesive market in India with one of the largest Bio-Adhesive .The product has been widely used across India by practicing doctors.

Ready-to-Fill Pellets & MUPS(Multiple Unit Pellets System)

Pellets Advantages of Immediate, Sustained, Extended & Delayed Release Pellets.

- To extended/delayed release technologies can be tailored to the desired release profile for a given drug. The release characteristics are customized on its pharmacokinetic profile and need of compliance and side effects in mind for patients.

- Pellet can be used to formulate tablets, capsules, and caplets that deliver single active compounds, as well as multiple active compounds, each requiring different release patterns, within a single dosage form.

- Due to pellets based NADS the distribution area increase thus reducing the potential of gastrointestinal side effects after ingestion. It also provides a safety feature in taking care of dose dumping as against tablets.

- Reduces peak /tough effect in blood levels to lessen the potential of toxicity or side effects

- Ready to fill pellets saves valuable time at customer end in realizing fast registration and introduction of products in market without incurring tedious product development costs.

- Our pellets containing appropriate active in percentage can be used to fill different strengths dosage form ,thus avoiding repetitious & costly strength specific validations.

- Pellets filled in transparent capsules provide aesthetic appeal with differentiation for marketing advantage compared to conventional tablet and capsule.

Multiple Unit Pellets System (MUPS) Advantages :

- Rapid but uniform transit of micro pellets contained in MUPS from the stomach into small intestine owing to their small size and thus lesser possibility of localized irritation, better and more uniform drug absorption and greater bio-availability.

- Uniform emptying of micro pellets from stomach into small intestine facilitates rapid dissolution of enteric coating and drug release resulting in early tmax and Cmax (peak time and peak plasma concentration) in case of delayed-release formulations. In case of controlled-release preparations, drug release is more uniform and possibility of dose dumping is avoided with minimized tendency for inter-subject variations.

- Smaller volume/size of tablet leads to better patient compliance than capsules.

Concord Drugs offer products and services of international standards through innovations with foresight of our responsibility towards the Society at large.

Tablets

The manufacturing areas are provided with separate facility for both Betalactum and non Betalactum Tablets and with sophisticated, modern equipment like R.M.G., F.B.D , Octacone Blender, GMP Model High speed compression machines, Alu-Alu pack, Blister and strip Packings to pack wide range of products.

Click Here to View Product List

Capsules

The manufacturing areas are provided with separate facility for both Betalactum and non Betalactum Capsules and with sophisticated, modern equipment like AF 90 , SA 9, Alu-Alu pack, Blister and strip Packings to pack wide range of products

Click Here to View Product List

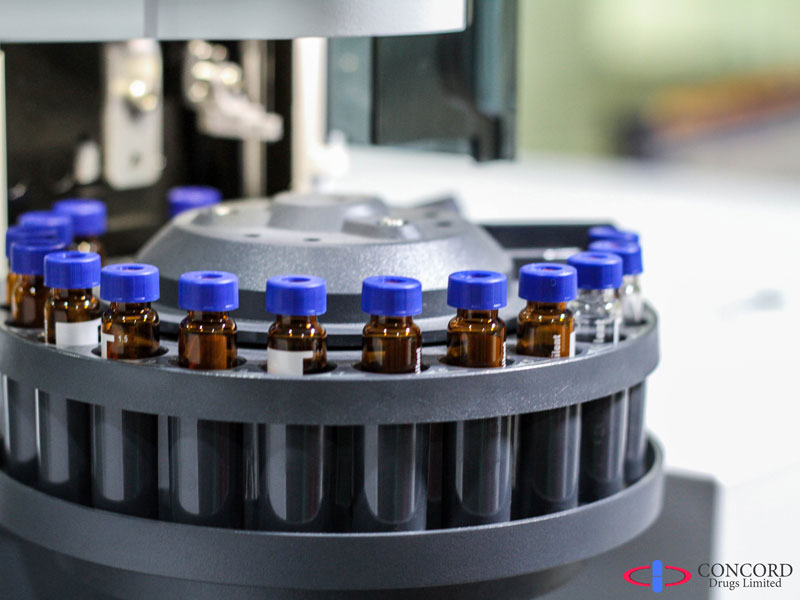

Injectables (Small volume parenterals, Dry powders)

The manufacturing areas are provided with different classified areas depend on the activity as per schedule M and respective GMP standards. Liquid filling and Dry Powder line has capacity to fill wide range of packs.

Click Here to View Product List

Liquid Orals (Syrup & Suspension)

Concord Drugs has started its Liquid Oral Manufacturing division in 2017 at Hyderabad.

Oral liquid dosage forms include solutions, syrups, suspensions. They offer better patient compliance in people who find swallowing pills or capsules difficult, and more flexible dosage control than a fixed-dose tablet. However, there are particular issues that arise in formulating and developing oral liquid dosages. These include the stability of the drug in solution, the solubility of the drug at the required concentration and the acceptability of the taste.

We have considerable experience of overcoming these challenges through the effective use of excipients to modify the behavior and properties of the formulation without impeding the efficacy of the API.

Click Here for Product List

Dry Syrups (Powder)

We at Concord Drugs Limited started division for manufacturing of Dry Syrups in the year 2021.

Dry powders / Syrups for oral suspension are powder mixtures that require the addition of water (reconstitution) at the time of dispensing and are mostly used in pediatric use. Manufacturing are is fully equipped with a capacity to manufacture 25,000 Bottles per shift.

Click Here for Product List

Hand Sanitizers

In the View of COVID – 19 Pandemic we have launched Hand Sanitizers wit Brand Name: PROTON SAFE

We have huge capacities to cater the needs in the wake of CORONA VIRUS. Our Hand sanitizer is made of Ethyl Alcohol and the composition is approved by WHO (World Health Organization.

We Manufacture Hand Sanitizers to many companies across India on Third Part Basis

Click Here for Images and Promotional Information

Ready to Fill Pellets & MUPS (Multiple Unit Pellets System) (SEMI FINISHED)

Pellets Advantages of Immediate, Sustained, Extended & Delayed Release Pellets.

- To extended/delayed release technologies can be tailored to the desired release profile for a given drug. The release characteristics are customized on its pharmacokinetic profile and need of compliance and side effects in mind for patients.

- Pellet can be used to formulate tablets, capsules, and caplets that deliver single active compounds, as well as multiple active compounds, each requiring different release patterns, within a single dosage form.

- Due to pellets based NADS the distribution area increase thus reducing the potential of gastrointestinal side effects after ingestion. It also provides a safety feature in taking care of dose dumping as against tablets.

- Reduces peak /tough effect in blood levels to lessen the potential of toxicity or side effects

- Ready to fill pellets saves valuable time at customer end in realizing fast registration and introduction of products in market without incurring tedious product development costs.

- Our pellets containing appropriate active in percentage can be used to fill different strengths dosage form ,thus avoiding repetitious & costly strength specific validations.

- Pellets filled in transparent capsules provide aesthetic appeal with differentiation for marketing advantage compared to conventional tablet and capsule.

Multiple Unit Pellets System (MUPS) Advantages :

- Rapid but uniform transit of micro pellets contained in MUPS from the stomach into small intestine owing to their small size and thus lesser possibility of localized irritation, better and more uniform drug absorption and greater bio-availability.

- Uniform emptying of micro pellets from stomach into small intestine facilitates rapid dissolution of enteric coating and drug release resulting in early tmax and Cmax (peak time and peak plasma concentration) in case of delayed-release formulations. In case of controlled-release preparations, drug release is more uniform and possibility of dose dumping is avoided with minimized tendency for inter-subject variations.

- Smaller volume/size of tablet leads to better patient compliance than capsules.

Concord Drugs offer products and services of international standards through innovations with foresight of our responsibility towards the Society at large.

Click Here for Product List

Tablets & Capsules

Tablets

The manufacturing areas are provided with separate facility for both Betalactum and non Betalactum Tablets and with sophisticated, modern equipment like R.M.G., F.B.D , Octacone Blender, GMP Model High speed compression machines, Alu-Alu pack, Blister and strip Packings to pack wide range of products.

Click Here for Product List

Capsules

The manufacturing areas are provided with separate facility for both Betalactum and non Betalactum Capsules and with sophisticated, modern equipment like AF 90 , SA 9, Alu-Alu pack, Blister and strip Packings to pack wide range of products.

Click Here for Product List

Injectables (Small Volume Parenterals , Dry Powders)

The manufacturing areas are provided with different classified areas depend on the activity as per schedule M and respective GMP standards. Liquid filling and Dry Powder line has capacity to fill wide range of packs.

Click Here for Product List

Liquid Orals (Syrups)

Concord Drugs has started its Liquid Oral Manufacturing division in 2017 at Hyderabad.

Oral liquid dosage forms include solutions, syrups, suspensions. They offer better patient compliance in people who find swallowing pills or capsules difficult, and more flexible dosage control than a fixed-dose tablet. However, there are particular issues that arise in formulating and developing oral liquid dosages. These include the stability of the drug in solution, the solubility of the drug at the required concentration and the acceptability of the taste.

We have considerable experience of overcoming these challenges through the effective use of excipients to modify the behavior and properties of the formulation without impeding the efficacy of the API.

Click Here for Product List

Dry Syrups (Powder)

We at Concord Drugs Limited started division for manufacturing of Dry Syrups in the year 2021.

Hand Sanitizers

In the View of COVID – 19 Pandemic we have launched Hand Sanitizers with Brand Name: PROTON SAFE